SOLDERED WIRE - PROFILE INSPECTION

Customer Need

The Customer used a continuous soldering application to manufacture a cable that was used as a part in their end product and were visually inspecting the wire after the soldered cable was already spooled. This was labor intensive and achieved inconsistent results as it varied from person to person inspecting it.

They wanted an application that would remove any subjectiveness as well as speed up the process. The inspection was to include voids (size and frequency), solder under fill, solder overfill, and solder blobs and mark the cable appropriately.

Solution

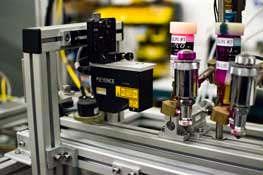

CSC designed and fabricated a 3d profiling system with 4 acetone based paint sprayers. The paint is used to mark the locations of the defects so they could be found later and be removed or repaired. The profile is created using a stationary 2D laser profilometer mounted above the line. The 3d image is processed then by the Keyence XG controller, the results of which were displayed through a custom PC application. The application is composed of multiple password protected access levels for operators, managers, and administrators. All of the criteria for pass and failure conditions of the various defects are user configurable and available at the manager level.

System Components

Keyence LJ-V Laser Profilometer

Keyence XG-8702 Controller

Encoder Products Encoder Splitter

Custom Spray Marking System

Fanless PC

Success

The system successfully met all FAT (factory acceptance test) and was delivered to the client ahead of schedule. The system ran successfully and allowed the client to secure a large contract that will allow them to increase production.