PCB HEAT STAKE POST HEIGHT MEASUREMENT

Customer Need

A medical device company was experiencing mis-alignment and fitment problems when trying to assemble their product. A Printed Circuit Board that was attached to the housing was heat staked in place and they found that the heat stakes were protruding too far and preventing the next piece that fit over it wasn’t fitting properly because the heat stakes weren’t being melted to the required height. They wanted an application that would allow them to pull components and perform an acceptance quality limit (AQL) test on them to determine if the batch was acceptable.

Solution

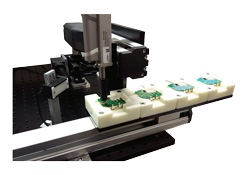

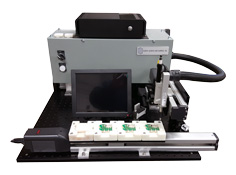

CSC designed and built a benchtop system that uses a digital contact sensor mounted on an X-Y stage to measure the height of each deformed stake (post) relative to an adjacent reference location on the PCBA. The system also uses a vision system to measure the gap between the PCBA and the pod body. Multiple devices can be tested sequentially without operator intervention.

System Components

Keyence GT2 Contact Probe

Keyence XG-7502 Controller

2MP Monochrome Camera

Fanless PC

Success

Two systems were successfully delivered to the customer on time and on budget. The implementation resulted in them being able to determine where in the production process the errors were occurring and assist them in correcting them to get the AQL within an acceptable range. Since the original order, two additonal systems have been fabricated and delivered.