BAND SAW AUTOMATION CONTROLS - RETROFIT

Customer Need

Due to the high cost of errors the client needed to find a way to automate the cutting of aluminum pipe which is between 4 to 24 inches in diameter, to a length of up to 60 feet. The client's original process was manual with 2 skilled operators using a tape measure and band saw.

Custom Systems and Controls was asked to design and fabricate a solution to effectively automate the original process so that it would increase accuracy and minimize costs with the following specifications.

- Retro-Fit controls into existing layout

- All hardware needs to fit into existing layout

- Accuracy better than 1/16"

Solution

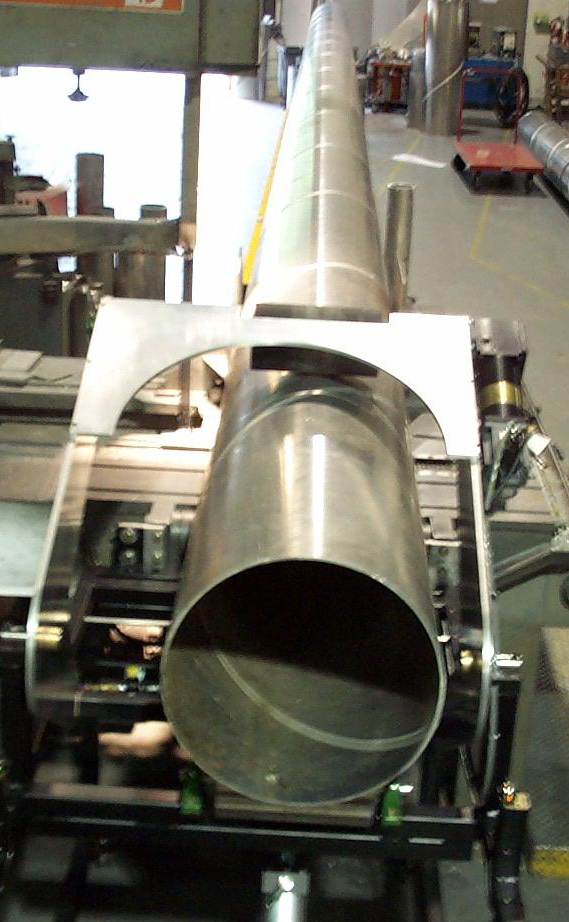

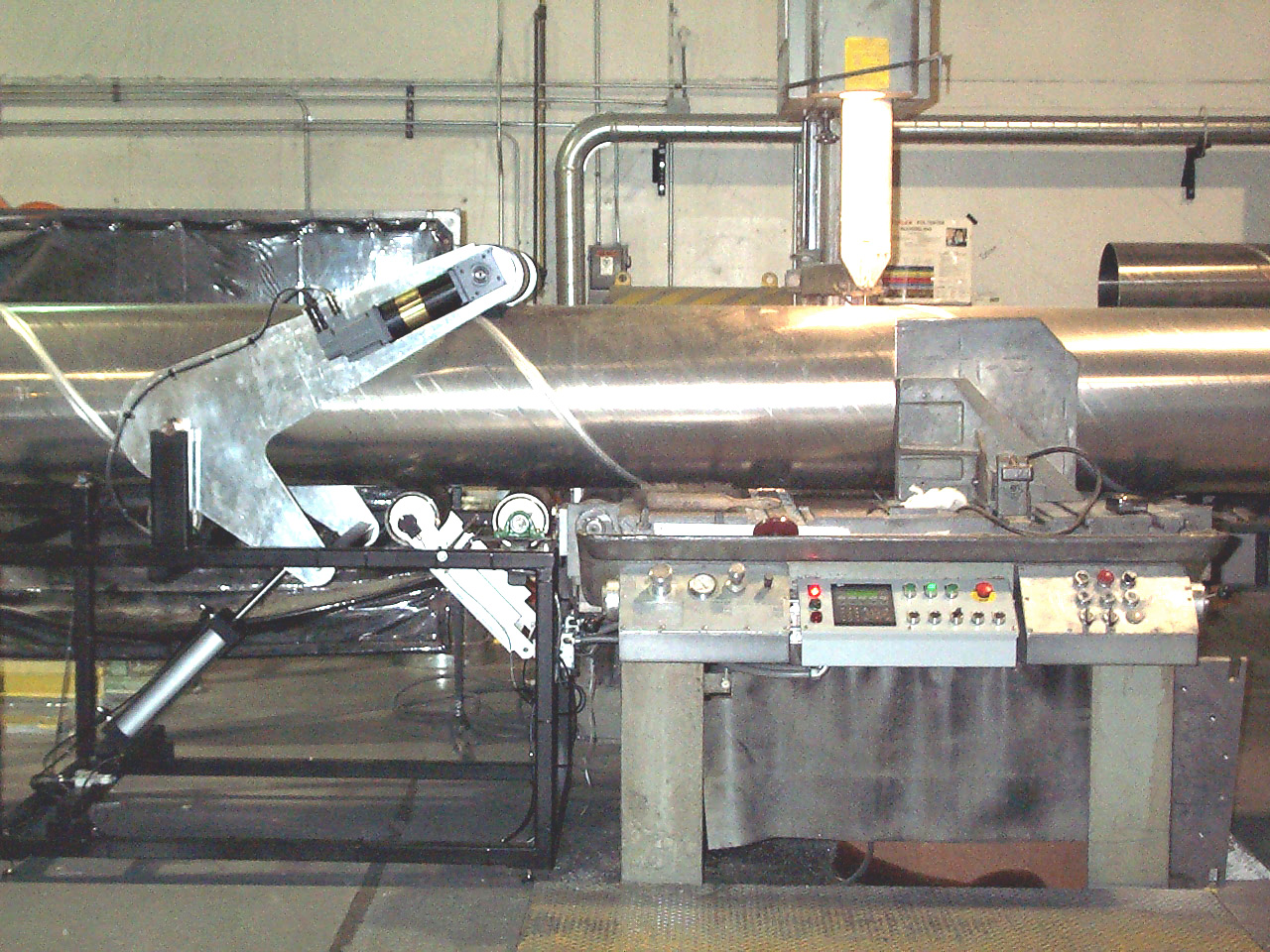

CSC designed and fabricated a conveyor and clamping system that would automatically feed the tubing to the appropriate length and allow the band saw to make its cut.

Some features of this project are:

- Clamping system to accurately hold tubing in place

- 60' of powered conveyor to facilitate loading

- 60' of unpowered conveyor to assist in moving cut material

- Custom servo drive system with ruggedized encoder to measure and index pipe

System Components

Mitsubishi PLC

Mitsubishi Servo

Custom Pneumatic Clamping System with End Detection

Success

The client was able to reduce labor cost by 50% by changing a 2 man skilled labor job into to a one man job that required 30 minutes of training. The automation process significantly reduced unnecessary wasted material and was accurate better than a 1/16 inch.