3-AXIS COORDINATE MEASURING

Customer Need

A manufacturer of an automotive part was experiencing inconsistent quality with their product. As a result of this, they wanted a system that would verify the connection of a mandrel and yoke assembly, insert an end plug into the bottom of the shaft and ensure the presence of a bellows.

The measurements required were the width, depth of the insertion and the height of the protrusion. It also had to be able to accommodate two variations of the product.

Solution

CSC designed and fabricated a semi-automated assembly cell with a frame made of structural steel members, a back plate in which the assembly tooling was located to fixture the part in a vertical axis. A container that is loadable from the rear of the machine will allow operators access to the end plugs. In addition, there was an interlocked chute with a mailbox type security features to allow the operator to place rejected parts.

The lower locating tooling was universal for both parts and fixed mounted to the back plate. The upper locating tooling was a change piece of tooling and mounted to a pneumatic slide to accommodate the two part’s lengths variance and yoke angular orientation. Two (2) pneumatic toggle clamps secured the sub-assembly in the locating tooling at the beginning of the process. Sensors in the tooling verified proper placement of the correct Slider Sub-Assembly in the locating tooling.

Two sets of X-Y-Z Voice Coil Actuators that consisted of linear profile rails and carriages, angle plates were mounted above the upper yoke and one set below the lower yoke. An IAI RCS3 series, servomotor driven linear press actuator with integral load cell force sensing will performed the end plug pressing.

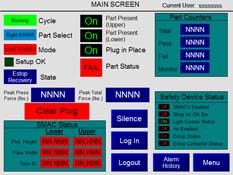

Once the operators arm was no longer present in the light curtain after placing a part in the fixture, the system would start the measurement and verification process. With a custom tip on the end of the actuator, it performs a series of measurements on the required areas. All with an accuracy of 1μm. A custom software program would allow the operator know if it passed or failed. It would also record all the information in a database and allow for reporting.

System Components

- SMAC Voice Coil Actuators with 1μm Encoders

- SMAC 4-Axis Controller

- Custom Steel Tube Frame

- Allen Bradley CompactLogix 5370 Controller with Integrated Motion

Success

The system successfully met all FAT (factory acceptance test) and was delivered to the client ahead of schedule. The system ran successfully and allowed the client to secure a large contract that will allow them to increase production.