TURBINE ENGINE PART - FIBER LASER MARKER

Customer Need

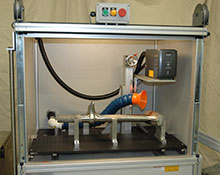

Custom Systems and Controls was asked to build a Laser Marking System to mark heavy steel castings in a very confined space.

Solution

CSC designed an fabricated a laser enclosure with a pneumatic vertical slide up door which requires a minimal room footprint and low headroom. The part is fixtured on easily machined and swapable supports which slide out for loading to prevent the operator from possibly damaging the laser head.

Custom software allows an operator to scan a traveller which sets the laser program, marking pattern, and prompts the operator. All data necessary for marking is loaded from the customer's existing database and the results of the operation are added to a customer defined table to facilitate part tracking and auditing.

System Components

Keyence MD-F3100 3 Axis Fiber Laser Marker

Keyence SR-600HA Barcode Scanner

Fumex FA-1 Fume Extractor

Fanless SSD PC

Custom Software

Custom enclosure with slide out drawer

Success

CSC was able to successfully complete the project on time and on budget. The client is able to run all programs from the custom software and make adjustments as needed. The unit has been in operation since installation with no major repairs and is still performing for the client.