RESISTIVE WELDING

Customer Need

The client had an existing welder that needed motion controls upgraded and a variable force welding head added. Custom Systems and Controls was asked to design and build an automated system to effectively perform with the following design specifications:

- Programmable from Excel

- Air Monitoring

- Safety Interlocks

Solution

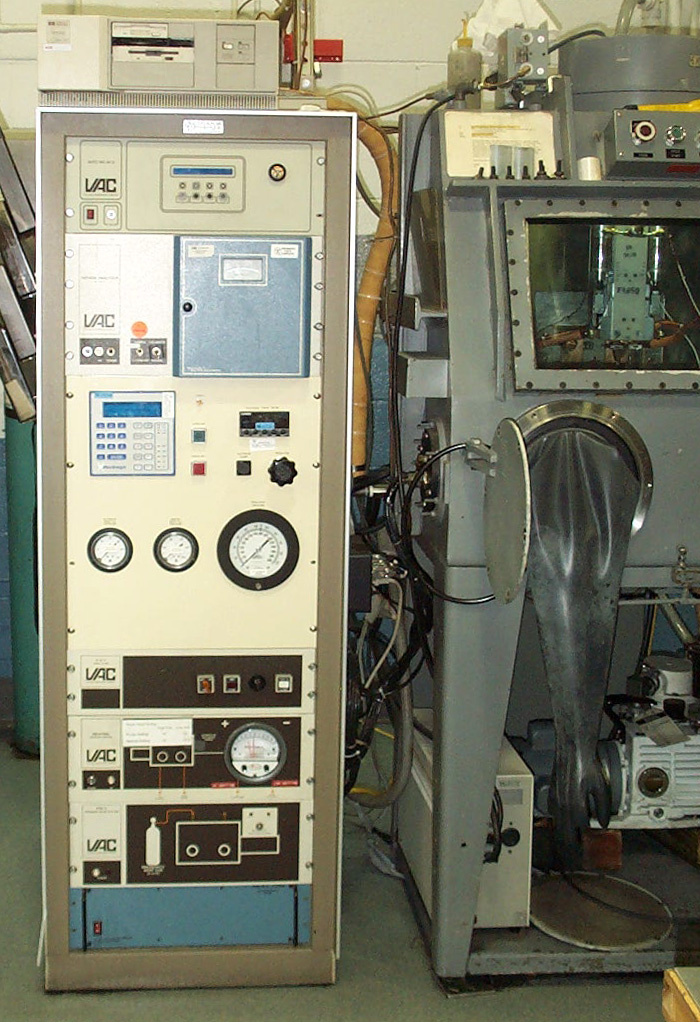

CSC designed and fabricated a new computer based control system to replace the current one. The system is designed to run a “program” contained in an Excel file on the panel PC. The panel PC communicates with the QMAC over a Cat5 Ethernet connection, telling the QMAC where to move each of the 4 axis and when to activate the various outputs. The QMAC tells the panel PC the status of each of the 4 axis, the status of the digital inputs, and the status of the digital outputs.

Some features of this project are:

- Panel PC

- 4 Axis of motion

- Remote operator station

- New weld head

System Components

Delta Tau Controller

Poseidon Panel PC

Compumotor Stepper Drives

Mitsubishi Servo Motor

Festo Fittings

Wieland Terminal Blocks

Success

CSC was able to successfully complete the project on time and on budget. The client is able to run all programs from Excel and capable of controlling each of the axes. This unit has been in operation for over 14 years with no major repairs and is still performing for the client.