Over the years CSC has had the opportunity to work on many different types of projects. These represent a small sampling of those and the different types of work we're capable of handling and excelling at.

Listed below are a few examples of our past projects:

|

Automotive Belt - CO2 Laser MarkerA laser marking system designed to clamp belts of various sizes for marking by a CO2 laser. The system is capable of marking fixed length straight, looped belts and continuous belts fed through the machine. |

|||

|

Automotive - Part InsertionA system to manually feed precut strips of a material and automatically install small plastic clips on them. The clips are installed at predetermined locations. Completed strips exited the machine at the far end. |

|||

|

Chlorine Gas ScrubberA by-product of the client's manufacturing process is chlorine gas. CSC designed a semi-custom molded scrubber control system that removes these fumes from the exhaust hood air prior to discharge into the atmosphere. |

|||

|

Facility RelocationCoordination and manufacture of the infrastructure related to the construction of the 35,000 square foot facility. All systems are interconnected with piping, electrical and warning/safety systems. |

|||

|

Filtration - CO 2 3-Axis Laser MarkerA laser marking system designed to mark various HDPE tubes and create identification labels with barcodes to apply to each tube. |

|||

|

Filtration - Web InspectionA vision inspection system to detect debris and defects in a web material. This was a retrofit onto an existing manufacturing line. |

|||

|

Medical Device - Automated Inline SolderingAn automated continuous soldering line integrating two materials. The system is capable of producing over 3km of material without a line stop. There is an inspection and marking system to detect defects. |

|||

|

Medical Device - Automated InspectionA fully automated vision inspection system capable of detecting the presence and proper installation of various components for a medical device. It was retrofitted into an existing manufacturing line to perform 100% inspection. |

|||

|

Medical Device - Electrical TestA system for measuring leakage current and battery voltage in a medical device. The system was be designed with two test fixtures for two different versions of assemblies. |

|||

|

Medical Device - Fiber Optic Cable TestingA fiber optic cable QA test unit with an emmitting diode and recieving sensor diode at either end that allows the client to take it on-site or use in-house. |

|||

|

Multi-Layer VacuumA system to more accurately control a vacuum sputtering system. Controls were designed to allow monitoring and control of chamber pressure with a simple user interface. |

|||

|

Portable Speaker - Fiber Laser MarkerA laser marking system designed to mark product information on a portable speaker housing. Markings include a 2D barcode, serial number, product number, UL certification, and others. |

|||

|

Resistive WeldingAn PC automated control system to retrofit motion controls and add a variable force welding head. |

|||

|

Sport Sensor - Charging StationA custom charging station for sports sensors with micro USB charging ports. LED lights indicate charging status. |

|||

|

Turbine Engine Component - Fiber Laser MarkerA laser marking system to mark part identification numbers on heavy steel castings in a very confined space. In addition, custom software allows an operator to scan a traveler to automate the process. |

|||

|

Fiber Optics - Vertical LatheA system to automate the controls of a precision vertically mounted machine lathe that contained a Oxygen/Hydrogen plasma torch, and gas delivery system. |

|||

|

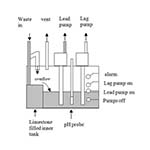

Waste Water TreatmentAn automated system to effectively to treat all lab waste generated at the facility prior to discharge into the sanitary waste system. |

|||

|

Web-Based VacuumAn automated system that allowed the client to automate all functions of the system from one easy-to-use interface. All start-up and shut-down functions were incorporated into this. |

|||

|

Web-EmbossingAn automated processing system capable of dispersing proprietary material onto a web system. It allowed the client to control all aspects of the process from one interface, and allows all rolls to function independently or synchronously. |